CAT Engine Course(Part 4) Cooling System

Cooling System

COOLING SYSTEM SCHEMATIC

This diagram shows the basic cooling system. We can use it to see the components of the system and see how they are connected. In the diagram, we see the engine block, cylinder heads (separate heads for each cylinder), coolant manifold, housing of the temperature regulators (thermostats), water outlets bypass line from regulator housing to water pump, water pump, water inlet from radiator or heat exchanger, coolant line to the aftercooler, and the oil cooler.

1. water pump

2. oil cooler

3. cylinder heads

4. water manifold (right side)

5. aftercooler

6. temperature regulator housing

7. bypass line from regulator housing to water pump.

COOLING SYSTEM FLOW

Coolant flow comes from the elbow which is connected to the radiator or other heat exchanger into the center of the water pump. The cooler flow is divided at the outlet of the water pump. One partflows to the aftercooler; the other part to the oil cooler.

Coolant sent to the aftercooler goes through the aftercooler and is sent by an elbow into a passage in the block near the center of the vee at the rear of the block. The coolant sent to the oil cooler goes through the oil cooler and flows into the water jacket of the block at the right rear cylinder. The coolant mixes and goes to both

sides of the block through distribution manifolds connected to the water jack of all the cylinders.

The main distribution manifold is located just above the main bearing oil gallery.

COOLING SYSTEM FLOW

The coolant flows up through the water jackets and around the cylinder liners from the bottom to the top. Near the top of the cylinder liners, where the temperature is the hottest, the water jacket is made smaller. This shelf (smaller area) causes the coolant to flow faster for better liner cooling. Coolant from the top of the liners goes into the cylinder head which sends the coolant around the parts where the temperature is the hottest. Coolant then goes to the top of the cylinder head and out through an elbow, one at each cylinder head, into a manifold, one for each back of cylinders. Coolant goes through the manifold to the thermostat housing.

The water pump is gear driven at 1-1/3 times engine speed for the 1300 to 1800 rpm high speed engine and 2 times engine speed for the 1300 rpm low speed engines.

COOLING SYSTEM SCHEMATIC

This diagram shows the basic cooling system. We can use it to see the components of the system and see how they are connected. In the diagram, we see the engine block, cylinder heads (separate heads for each cylinder), coolant manifold, housing of the temperature regulators (thermostats), water outlets bypass line from regulator housing to water pump, water pump, water inlet from radiator or heat exchanger, coolant line to the aftercooler, and the oil cooler.

1. water pump

2. oil cooler

3. cylinder heads

4. water manifold (right side)

5. aftercooler

6. temperature regulator housing

7. bypass line from regulator housing to water pump.

COOLING SYSTEM FLOW

Coolant flow comes from the elbow which is connected to the radiator or other heat exchanger into the center of the water pump. The cooler flow is divided at the outlet of the water pump. One partflows to the aftercooler; the other part to the oil cooler.

Coolant sent to the aftercooler goes through the aftercooler and is sent by an elbow into a passage in the block near the center of the vee at the rear of the block. The coolant sent to the oil cooler goes through the oil cooler and flows into the water jacket of the block at the right rear cylinder. The coolant mixes and goes to both

sides of the block through distribution manifolds connected to the water jack of all the cylinders.

The main distribution manifold is located just above the main bearing oil gallery.

COOLING SYSTEM FLOW

The coolant flows up through the water jackets and around the cylinder liners from the bottom to the top. Near the top of the cylinder liners, where the temperature is the hottest, the water jacket is made smaller. This shelf (smaller area) causes the coolant to flow faster for better liner cooling. Coolant from the top of the liners goes into the cylinder head which sends the coolant around the parts where the temperature is the hottest. Coolant then goes to the top of the cylinder head and out through an elbow, one at each cylinder head, into a manifold, one for each back of cylinders. Coolant goes through the manifold to the thermostat housing.

The water pump is gear driven at 1-1/3 times engine speed for the 1300 to 1800 rpm high speed engine and 2 times engine speed for the 1300 rpm low speed engines.

Coolant comes from the aftercooler and goes into this

After the coolant goes through the oil cooler, it is sent into the engine block at the right rear cylinder. Coolant from the oil cooler and aftercooler mix (comes together) in the block and goes through the cylinder heads to the left and right water manifolds in the “vee” of the engine.

The bypass line goes from the temperature regulator housing to the inlet of the water pump. The regulators in the housing control coolant flow to the radiator or heat exchanger to regulate the temperature in the cooling system. When the coolant temperature is not high enough to open the regulators, the coolant will flow through the bypass line (bypassing the radiator) to circulate through the engine for quick warm-ups.

Four temperature regulators are in the thermostat housing.The housing has an upper and lower section. The sensing bulbs of the four temperature regulators are in the coolant in the lower section of the housing. Before the regulators open (upper inset), cold coolant is sent through the bypass line to the inlet of the water pump. As the temperature of the coolant increases to 88°C (180°F) and the regulators start to open (lower inset), coolant flow in the bypass line is stopped and coolant is sent through the outlets to the radiator or heatexchanger.

Coolant capacity is given in the Operation Guide for the engine only. Total system capacity will depend on the size of the radiator or heat exchanger. To prevent the coolant from freezing, it should have a mixture of 50 percent pure water, 50 percent

permanent antifreeze and a 3 to 6 percent concentration of corrosion inhibitor.

Here we see the housing for the temperature regulators (thermostats) and the four sleeve-type temperature regulators. The housing of the temperature regulator is above the front gear cover and supported by a compartment connected to the right and left water manifolds that are located above the cylinder heads.

Each of the regulators is positioned in a counterbore and has a lip-type seal.

Here the temperature regulator and seal have been removed from the housing. The smaller barrel portion of the regulator is the part that comes in contact with the seal.

When the regulator is closed (engine cold) coolant goes through the regulators. The coolant returns to the inlet of the water pump by way of the bypass

pipe (which is fastened to the opening in the front of the housing)

and does not get to the radiator.

When the regulator is open (engine hot) coolant goes through the

When the regulator is open (engine hot) coolant goes through the

regulator out the side of the housingand then to the radiator for

cooling. On marine applications, the position of the regulator housing

will be upside down from the position in the photo.

The seals can be removed and replaced. To replace the seals, a seal driver must be used. To replace a seal, remove the old seal and clean the counterbore. Now install the seal in the housing with the lip of the seal away from the regulator.

The seals can be removed and replaced. To replace the seals, a seal driver must be used. To replace a seal, remove the old seal and clean the counterbore. Now install the seal in the housing with the lip of the seal away from the regulator.

Use a 1P529 Handle and a 1P489 Drive Plate to drive the seal into position in the housing.

When regulators and seals are replaced, the machinedsurfaces of the housing and cover must becleaned and a new gasket installed.

When regulators and seals are replaced, the machinedsurfaces of the housing and cover must becleaned and a new gasket installed.

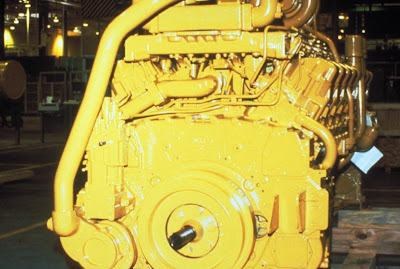

COOLING SYSTEM GENERATOR SET

On the right, we can see the coolant outlet line and the coolant inlet line at the bottom. The outlet line and inlet line are connected to a radiator outside the building.

The bypass line goes from the top of the thermostat housing to the inlet side of the water pump. We can also see the fuel filter housing and oil filter

housing on this generator set arrangement.

Comments

visibility, Increase traffic to blogspot and website

http://freeurlsubmitdirectory.blogspot.com/

You can add business opportunities with my blog which to be Multiply Make Money Online Alternative, It help increase revenue from ur blog/Website so much.

Detail More at http://businesssitesguide.blogspot.com ;) .

is getting more from this web page, and your views are pleasant in support of new visitors.

my website - wall shelves

Marine Surveyor

diesel engine spare parts

Please visit:

http://www.marineenginers.blogspot.ru

Engine manuals:

http://marineenginers.blogspot.ru/p/engine-manuals-manburmeister-wain.html

Vessel manuals:

http://marineenginers.blogspot.ru/p/my-vessel-manuals.html

After cooler temperature shows high about 50deg

Warning set is at 47deg

What shall I do

3516b cat

Find auto parts online