CAT Engine Course (Part 5) Lubrication System

The engine oil pressure has a normal operating range from 345 to 480 kPa (50 to 70 psi) and will be approximately 450 kPa (65 psi) at full load rpm. Flow of oil through the engine at rated rpm is approximately 340 litres/min (90 gpm).

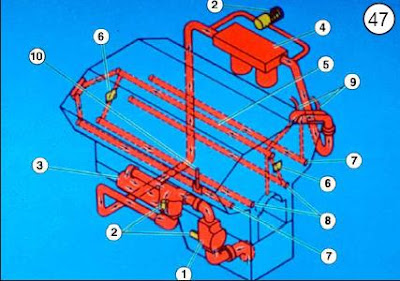

In this diagram of the lubrication system, we see the oil reservoir (sump in the oil pan), the oil pump (1) with a pressure relief valve (2); the oil cooler (3) with a bypass valve (2); the oil line from the cooler to the oil filter base/housing (4); with bypass valve (2) [one bypass valve for each filter]. The oil goes from the oil filters through the oil line to the oil elbow (manifold) on the left top front of the block.

The oil pump takes oil from the sump and sends it through the oil cooler, oil filters, and into the oil elbow (manifold).

Oil is sent to the turbochargers through outside lines (9) that are connected to the elbow on the left from (if turbocharger is top mounted). Turbocharger drain lines empty into the camshaft compartments through the camshaft side covers (10).

In the elbow (manifold), the oil is divided; one branch is sent to a camshaft oil gallery (7) below the camshaft and fuel control shaft, the other branch to a main oil gallery (5) which is above the main bearings of the crankshaft and on the centerline of

the block.

The main oil gallery (5) sends oil through vertically drilled passages to each main bearing, then through the crankshaft to each connecting rod bearing.

The oil that flows to the rear of the main oil gallery is sent up to the rear top of the block into an adapter (elbow manifold). The adapter sends the oil again into a camshaft oil gallery (7) in the block to the passage below the right camshaft.

The adapter also has plugs that may be removed to supply oil when the turbochargers are mounted on the rear of the engine.

The inset on the right of the diagram shows the oil passages on the right side of the engine. The oil in camshaft oil gallery (7) on the left side and the right side below the camshafts sends oil to the camshaft journals (11). The oil goes through hollow dowels to the cylinder heads through passages to the three lifters (two lifters for

valves, one for the injector) and the rocker arm shaft (12).

Oil is sent from each end of the main oil gallery (5) through small passages to the sequence valves (6). The two sequence valves control oil flow into piston cooling jet manifolds. There is one sequence valve on the left front of the block for the left passage and one on the right rear of the block for the right passage.

The purpose of the valves is to stop oil flow into the piston cooling jet manifold until oil in passage (5) has more than 140 kPa (20 psi) pressure. During engine start-up, the sequence valves decrease the time needed for the oil pressure to come up in the

main oil gallery to the main and connecting rod bearings. The sequence valves also hold the oil pressure up during engine idling, especially when the oil is hot, and parts are worn.

When the oil pressure is more than 140 kPa (20 psi), the sequence valves open and let oil go to the lower small passages (8) alongside of the crankcase. This oil is sent to the piston cooling jets (one for each piston). Each cooling jet has two openings. As oil is forced through each opening, one stream (spray) of oil is sent to a passage in the bottom of the piston which takes the oil to a circular manifold inside the piston and cools the piston. The other stream of oil hits the piston underside to cool it

and give lubrication to the piston pin and bearing.

The inset on the right of the diagram shows the oil passage to the gear train. Oil is sent to the front and rear gear trains from the oil passages below the camshafts (7) through passages drilled in the front and rear housings and the front and rear

block face.

The oil pump (1) and pressure relief valve (2) can be seen here.

The oil pressure relief valve is in the oil pump body and keeps the oil at the correct pressure. It opens at above normal pressures and sends the extra oil back to the pump inlet. Oil pressure must be measured when the engine is at normal temperature of operation. Also, oil pressure must be measured at a location (tap) AFTER the oil

has gone through the oil cooler and filters. Oil pressure can be measured on each side of the block at the oil gallery plug.

Here we can see the:

1. oil cooler

2. oil line from the oil pump to the oil cooler

3. oil line to the filter base housing on the left side of the engine

The oil cooler (1) is on the right side of the engine and is a tube core-type. Coolant goes through tubes in the cooler, and oil goes around the outside of the tubes. The oil cooler supply line (2) is on the outside of the cooler. The oil flows through the supply line through the cooler to the oil line to the filter base housing (3). On the vehicle arrangement, the oil line goes under the oil pan to the filter base housing on the left side of the engine.

The oil cooler bypass valve is in the oil cooler housing. The oil cooler bypass valve permits oil to go around the cooler when the oil is cold and thick or when there is a restriction in the cooler. The bypass valve will open when there is a pressure

difference of 160 to 200 kPa (23 to 29 psi) across the oil cooler (from the inlet of the cooler to the outlet of the cooler).

This is the oil line (arrow) from the oil cooler to the filter base housing which goes under the oil pan. Also we can see the oil pan is held to the bottom of the block with bolts. The bolts go through the block and are turned into threaded holes in the pan. To improve service on some arrangements, the bolts go through the oil pan to the block.

VEHICLE FILTER ARRANGEMENT

On the left side of the engine, we see the three oil filters. The oil goes from the filter base housing to the manifold (elbow) on the front left top of the block. The oil flow

from the oil cooler goes through the line on the right into the filter base/housing and to the oil filters. (The oil filters shown are full-flow type spin-on filters.)

Each oil filter has a bypass valve behind the plates (see arrows). When the oil filters have a restriction, the bypass valve opens and sends the flow directly to the

oil line on the left which sends the oil to the block.

Each oil filter bypass valve will open when there is a pressure difference of 180 to 200 kPa (26 to 32 psi) across the filter (from the inlet side of the filter to the outlet side of the filter).

NOTE: Other applications of this engine can have the oil

filters at other locations.

Use a strap wrench , if needed, to remove the oil filters.

Change the oil filters when you change the engine oil at the service interval given in the Operation Guide.

Before installing the oil filters, be sure the old gasket is removed and the filter base is clean.

To install the oil filter, put clean oil on the gasket and turn the filter on the filter base until it contacts the base. Turn the filter 3/4 of one turn (270 degrees) more.

Put more oil in the engine when the oil level is at the ADD oil mark on the gauge.

Change the oil in the engine as recommended in the Lubrication and Maintenance Guide.

CAUTION

Vehicle engine dipsticks will be marked on both sides.

Be sure to read the correct side. The other side will read ADD, HOT-RUNNING.

The small lines going from the front, left oil manifold (elbow), sends oil to the turbochargers when they are top mounted. The large line from the bottom of the turbocharger is the oil drain which returns the oil to the camshaft compartment and

crankcase.

On the right rear of the engine block is the adapter (elbow manifold). Oil is sent from the main oil passage (gallery) to the top of the block. The adapter sends the oil into the camshaft bearing oil gallery. When the turbochargers are rear mounted, such as a Generator Set, Marine Engine, or Marine Auxiliary Engine, oil for the turbochargers comes from the two large plugs in the adapter.

OTHER ENGINES

Other engines (Industrial, Generator Sets, Marine and Marine Auxiliary Engine arrangements) have the oil filter housing (2) mounted across the front of

the engine.

Here we can see the:

1. drain valve

2. filter housing

3. bypass valve; and

The filter housing(2) has three (3) filter elements. The filter housing has a single bypass valve (3). On vehicular engines, there is one bypass valve for each filter. The oil inlet line goes from the oil cooler to the filter housing. The oil outlet line goes

from the oil filter housing to the oil manifold (elbow) on the block. Clean oil from the filters goes into the block in the same location as the vehicle engines.

The filter elements should be changed when the engine oil is changed. To install new filter elements,

open the drain valve (1) and drain the oil from the filter housing. Then remove the cap from the end (right-hand side) of the filter housing.

Remove the three filter elements and clean the filter housing with a clean lint-free shop towel.

Install new filter elements, a new seal, if needed.

Put the cap on the filter housing. After the engine is started, check the cap and seal for leaks.

A duplex oil filter is shown here.

Here we can see the crankcase dipstick on this industrial/generator set engine. There are either right-hand or left-hand locations for the dipstick

on the different engine arrangements.

Be sure there is oil in the sump before starting the engine. Then check the oil level with the engine idling and with the oil hot. The oil must be checked daily or every ten service meter units.

The oil must be between the “ADD” and “FULL” marks on the oil level dipstick.

Comments

Money Making and Blogging Tips

Anto Online Jobs