Classification of Centrifugal Pumps

Centrifugal Pump Classification by Flow

Centrifugal pumps can be classified based on the manner in which fluid flows through the pump. The manner in which fluid flows through the pump is determined by the design of the pump casing and the impeller. The three types of flow through a centrifugal pump are radial flow, axial flow, and mixed flow.Radial Flow Pumps

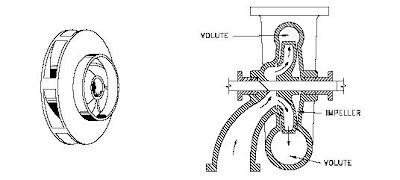

In a radial flow pump, the liquid enters at the center of the impeller and is directed out along the impeller blades in a direction at right angles to the pump shaft. The impeller of a typical radial flow pump and the flow through a radial flow pump are shown in Figure 6.

Fig 6 Radial Flow Centrifugal Pump

Axial Flow Pumps

In an axial flow pump, the impeller pushes the liquid in a direction parallel to the pump shaft. Axial flow pumps are sometimes called propeller pumps because they operate essentially the same as the propeller of a boat. The impeller of a typical axial flow pump and the flow through a radial flow pump are shown in Figure 7.

Fig 7 Axial Flow Centrifugal Pump

In an axial flow pump, the impeller pushes the liquid in a direction parallel to the pump shaft. Axial flow pumps are sometimes called propeller pumps because they operate essentially the same as the propeller of a boat. The impeller of a typical axial flow pump and the flow through a radial flow pump are shown in Figure 7.

Fig 7 Axial Flow Centrifugal Pump

Mixed Flow Pumps

Mixed flow pumps borrow characteristics from both radial flow and axial flow pumps.

As liquid flows through the impeller of a mixed flow pump, the impeller blades push the liquid out away from the pump shaft and to the pump suction at an angle greater than 90o. The impeller of a typical mixed flow pump and the flow through a mixed flow pump are shown in Figure 8.

Fig 8 Mixed Flow Centrifugal Pump

Mixed flow pumps borrow characteristics from both radial flow and axial flow pumps.

As liquid flows through the impeller of a mixed flow pump, the impeller blades push the liquid out away from the pump shaft and to the pump suction at an angle greater than 90o. The impeller of a typical mixed flow pump and the flow through a mixed flow pump are shown in Figure 8.

Fig 8 Mixed Flow Centrifugal Pump

Multi-Stage Centrifugal Pumps

A centrifugal pump with a single impeller that can develop a differential pressure of more than 150 psid between the suction and the discharge is difficult and costly to design and construct. A more economical approach to developing high pressures with a single centrifugal pump is to include multiple impellers on a common shaft within the same pump casing. Internal channels in the pump casing route the discharge of one impeller to the suction of another impeller.

Figure 9 shows a diagram of the arrangement of the impellers of a four-stage pump. The water enters the pump from the top left and passes through each of the four impellers in series, going from left to right. The water goes from the volute surrounding the discharge of one impeller to the suction of the next impeller.

A pump stage is defined as that portion of a centrifugal pump consisting of one impeller and its associated components. Most centrifugal pumps are single-stage pumps, containing only one impeller. A pump containing seven impellers within a single casing would be referred to as a seven-stage pump or, or generally, as a multi-stage pump.

A centrifugal pump with a single impeller that can develop a differential pressure of more than 150 psid between the suction and the discharge is difficult and costly to design and construct. A more economical approach to developing high pressures with a single centrifugal pump is to include multiple impellers on a common shaft within the same pump casing. Internal channels in the pump casing route the discharge of one impeller to the suction of another impeller.

Figure 9 shows a diagram of the arrangement of the impellers of a four-stage pump. The water enters the pump from the top left and passes through each of the four impellers in series, going from left to right. The water goes from the volute surrounding the discharge of one impeller to the suction of the next impeller.

A pump stage is defined as that portion of a centrifugal pump consisting of one impeller and its associated components. Most centrifugal pumps are single-stage pumps, containing only one impeller. A pump containing seven impellers within a single casing would be referred to as a seven-stage pump or, or generally, as a multi-stage pump.

Comments

Centrifugal Pump||Centrifugal Water Pump

Vertical Turbine Pumps keep it up bro...

Hydraulic Valves Dealers Mumbai

Hydraulic Powerpack Dealers Mumbai, AC DC Power Packs Mumbai

thanks a lot for sharing

End Suction Centrifugal Pumps In California

Centrifugal Pumps

https://www.exltech.in/mechanical-design-training.html

Pneumatic Operated Ball Valve